A rookie operator armed with John Deere cutting edge automation goes up against an operator with 50 years of harvest experience – see the outcome on video

John Deere has loaded its suite of automation functions on a groundbreaking S7 Series combine harvester to see if a next-generation farmer can hold their own when pitted against one of Australia’s most experienced operators.

In this ultimate man versus AI test that took place in the most recent wheat harvest, two new S7 900 harvesters ran alongside each other, one driven by an operator with more than 50 harvests under his belt, Joe Cornish, and the other by a 25-year-old fifth generation farmer, Angus Carrigan.

The harvester Angus was operating the benefit of all available automation functions, while veteran operator Joe switched them off, relying instead on his five decades of instinct and experience.

The end result of this clash was so dramatic it was turned into a docuseries called “Harvest S” that captures all the dust, drama and excitement as the S7 900s vie for most tonnage, least grain loss and the greatest productivity.

John Deere S7 Series combine harvesters can be equipped with either a JD14 13.6-litre engine, or a JD9 9-litre engine set at a Tier 3 emissions level.

The S7 900 has rated power of 405kW (543hp) and maximum power of 460kW (617hp) and has been engineered to produce higher power at lower RPMs, and offer all-condition performance through advanced diagnostic capabilities.

The set was a dusty paddock in Gurley NSW

“Conditions were tough at the test site at Gurley in northwest NSW, where there was a big wheat crop starting to lean over,” said Ben Kelly from John Deere who oversaw the challenge.

“But that’s what we wanted, to put the S7 through tough conditions in a real-world environment,” Ben Kelly added.

“And we could not have had two better competitors. We found one of the most experienced harvest contractors in Australia in Joe, who’s been farming since 1982, and asked him to drive the S7 manually for four hours without using any of the tech tools.”

“And then we put Angus, one of a new generation of farmers, in an S7 with all the most current technology at his disposal to see if he could match Joe’s productivity, capacity, and efficiency,” Ben Kelly enthused.

The engineering premise behind the John Deere S7 is that it’s packed with onboard technologies that enable it to level up the performance of even the most novice operator.

Predictive Ground Speed Automation lets forward cameras “see” the crop 8.5 metres ahead of the machine in conjunction with pre-harvest satellite images to generate a predictive paddock map. The combine then automatically adjusts speed to match the conditions and maintain optimum harvesting pace.

Harvest Settings Automation delivers an effortless way to lock in grain quality consistency. An operator simply sets the desired grain loss, foreign material and broken grain limits, and the S7 Combine takes care of the rest, self-optimising on the go to hit desired targets.

The benefits across the day, and the entire season, can increase productivity by up to 20%* and help address skills gaps and operator fatigue during the critical harvest period.

For experienced operator Joe, the the John Deere S7 was a far cry from his early days contracting, when guidance technology was a piece of rope dangling from a pipe at the front of the tractor.

“I’m very sceptical about this sort of stuff, but you can always be proven wrong,” Joe Cornish was heard to say.

“The main thing is keeping it consistent. Stoppages cost a lot of money,” Joe Cornish added.

Meanwhile fifth fifth-generation farmer Angus Carrigan with a passion for tractors and sees John Deere technology as making the job “a lot easier”.

“The use of cameras to see something coming means less time for me pulling straw out of blocked headers, and more time in the paddock is crucial,” Angus qualified.

“One of our challenges is finding skilled labour, and the current tech will help with that as well,” Angus adds.

As the grain flowed and the giant headers combed the paddocks, the two operators appeared to be neck and neck.

But, arriving back at test centre HQ, it was clear that the Predictive Ground Speed Automation had given Angus the edge in maintaining a consistent speed and high productivity, staying below one per cent grain loss limit.

“I think the front made it a lot easier to follow the ground, it sped up itself and kept it a pretty consistent load the whole time, which was great,” Angus pointed out.

Joe matched the grain loss, but his average speed had dropped to 10kph as he slowed to unload to the chaser bins, and altered speed to match the variable crop conditions.

For Max Cusack, a John Deere production systems specialist, the match proved that technology can “bridge the gap” in experience.

“The S7 technology doesn’t unlock a hidden extra bit of mechanical performance, but what it does unlock is consistent mechanical performance,” Max explained.

“So, if you can get operators in the cab, technology can bridge that gap in experience,” Max adds.

Post-credits to the main scene

Afterwards, Joe Cornish stepped back into the S7 with the full suite of automation technology turned on and was quick to see the benefits.

“It’s definitely a lot easier to operate,” Joe Cornish accepted.

“I really liked Machine Sync unloading, the ease of filling the bin. I can see why it would be good for operators who aren’t so highly skilled,” Joe Cornish adds.

This was just one of the tests run at the beginning of the 2024 Harvest season where John Deere had 10 Harvest Automation combines operating and the results of those machines in a variety of conditions have been collated to summarise the performance of what Predictive Ground Speed Automation and Harvest Automation means for growers.

To catch the full benefit of the operator versus AI harvest test, watch “Harvest S” and see the results for yourself. Simply log onto the John Deere Australia and New Zealand YouTube channel, using the links here.

Part 1: https://youtu.be/1kttySM4ALw?si=waY95xebdfnOZ_3S

Part 2: https://youtu.be/VEZMZnSzYsk?si=BO_rKwlV2iX2bEJW

*Based on anonymised Ops Center data comparing John Deere combine models with and without Predictive Ground Speed Automation. Productivity represented by tonnes of crop per hour. Results will vary depending on model, crop type, paddock and operating conditions.

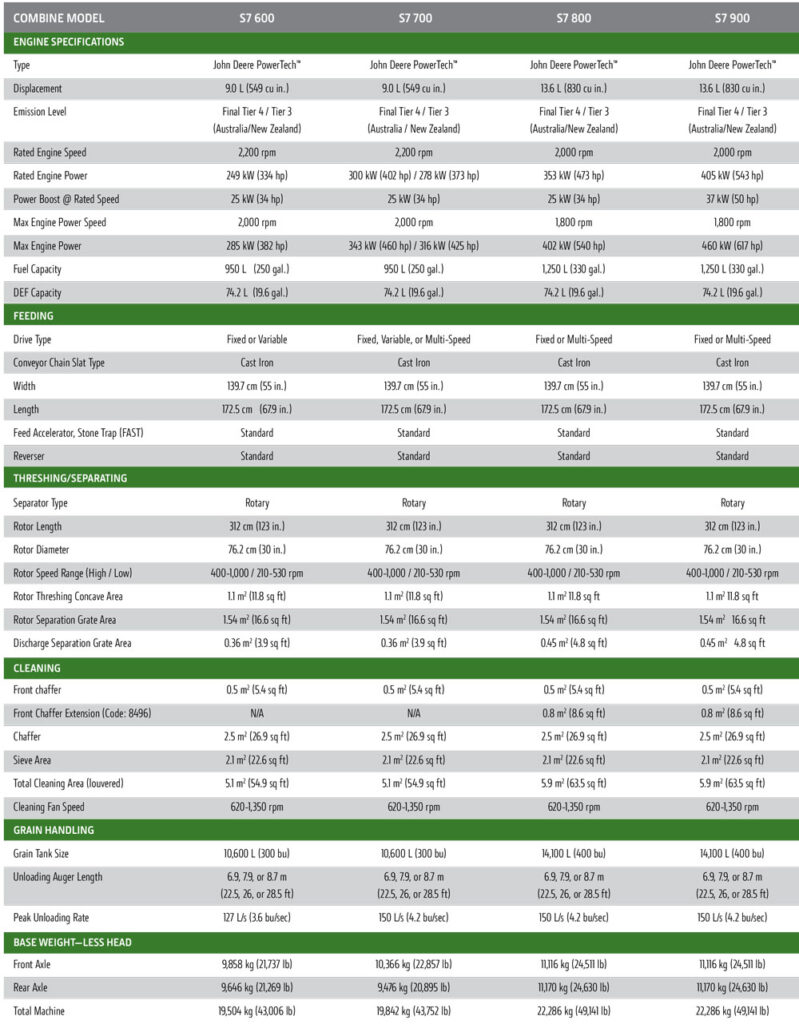

John Deere S7 Series combine specifications