The 2024-25 seeding season was a record breaker for area planted but not all regions had a seeding rig that suited ground conditions

With the 2025-26 planting season completed, it’s the perfect time to assess the equipment’s performance and ask a simple question: Is it keeping up with demand, or are breakdowns slowing everything down.

Inefficiency from running older rigs or an inappropriate setup is costing many farm operations time and money at planting, and also resulting in lower yields than could be achieved by more accurate placement.

Upgrading is the obvious solution when older seeders start to require more maintenance as they age, as they can throw off the entire schedule, especially when they break down. They bring with them the satisfaction of fewer interruptions, ensuring the task stays on track when it matters most.

Many operators who switch to more current seeding rigs quickly appreciate how they are also built to last longer-term, with the advantage of being able to add more current components and even technology

A current seeding rig integrates seamlessly with GPS, auto-steer, and variable-rate technology, improving seed placement and input efficiency. By optimising these factors, yields are improved from every hectare.

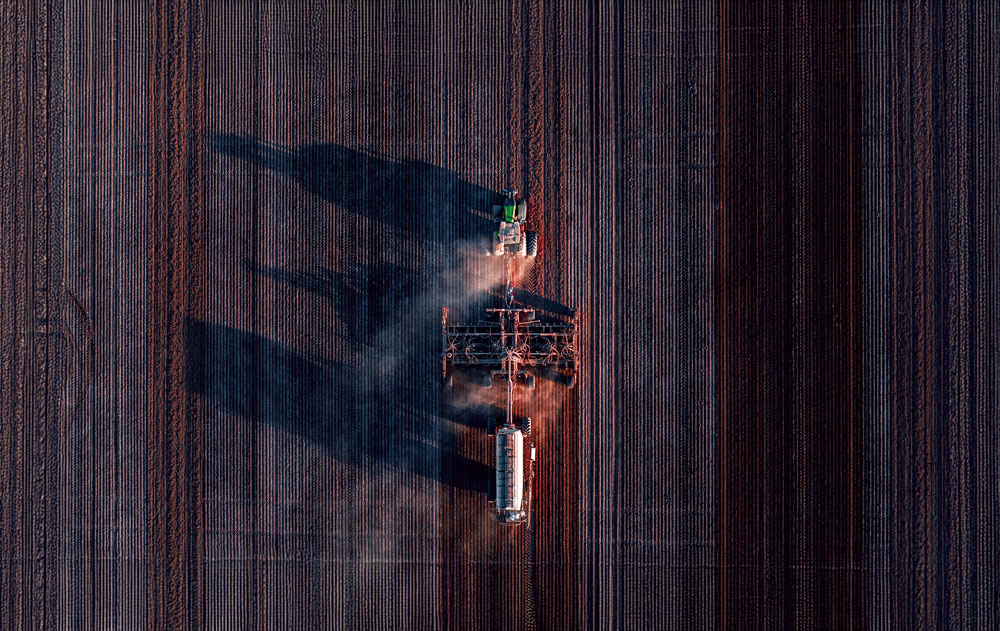

Larger air carts and bars reduce refill stops and cover the ground more quickly with each pass, a big plus to streamlining operations. Despite their additional working width, a current seeding rig is designed to be easier to tow and is more fuel-efficient, helping to lower costs.

Operators agree that precise placement is key to maximising yields, yet many farm operations continue to run older seeders that often struggle with accuracy, leading to uneven seed depth and poor germination.

Making the upgrade to more current equipment has ensured consistent placement, reducing soil disturbance and promoting stronger, more uniform crop emergence for many farm operations over the past three seasons. And resultant record yields have backed this up.

On-farm equipment upgrade advancements aren’t just about convenience, they do directly impact a farm operation’s bottom line.

Varying ground conditions from dry to wet, depending on each season, mean that many local farming regions demand much tougher, high-performance equipment than is currently being run.

If any of this resonates, upgrading your seeding rig could be your best investment for the next big plant. But it needs to be ordered in advance.

Bourgault 4420DKD Deep Knife Drill

Bourgault has released what it terms the ultimate planting bar for local growers, after substantial engineering and tailoring of the 4420DKD™ (Deep Knife Drill™) was done with the help of local growers.

The development of the 4420DKD has given local growers exactly what they need for varying ground conditions, the ability to deep-cut and with easily adjustable seed depth and packing pressure.

First launched for the 2024 season, the 4420DKD is a testament to Bourgault’s commitment to ensure local growers achieve optimal seeding applications with purpose-built solutions.

The 4420DKD combines a robust, easy-to-adjust deep knife™ opener with a durable and versatile frame that can be paired with any Bourgault Air Cart and accommodate on-board liquid tanks.

This model has set a high standard for precision seeding with an innovative design that allows farmers to penetrate the soil to greater depths, facilitating improved fertiliser separation and precise seed placement.

The 4420DKD is giving local operators exactly what they need in performance, and the seed placement is always precise, and germination is always even.

Due to its good flotation design, it’s very even and accurate across the whole bar.

And with the advantage of dual-tine DK™ (Deep Knife) openers, the 4420DKD can penetrate to soil depths of 120 to 165mm, to ensure growers get the required fertiliser separation and precise seed placement.

Operators are also blessed with an on-the-go adjustable hydraulic breakout on the openers in a force range of 68 to 450kg to handle a wider range of soil conditions and achieve consistent depth.

The 4420DKD drill is highly compatible and can be paired with the for example, Bourgault’s TruTrac Coulter system to optimise soil throw and residue management in high-stubble paddocks.

Working with the most current frame design, growers can be assured they have quality long-term inclusions in the build, such as a floating hitch as standard and a steerable front axle.

Choose from a 12 or 18m working width, with both models able to fold to 5.5m for quick and easy transportation.

Bourgault’s 4420DKD is adaptable to a wide range of ground conditions and planting requirements with row spacings of 250 to 300mm, while the heavy-duty frame option allows for a pair of liquid tanks with a total capacity of 5400 litres to be fitted.

And while this is a big capacity planting bar, put aside any concerns about soil compaction issues as the weight is handled by Hi-Flotation tyres fitted as standard.

For more information about the Bourgault 4420DK planter design benefits, use this link or scan the QR code to chat with your local Bourgault Australia dealer, or call on tel: +618 9399 9700.

Find out more about the industry-leading seeding technology Bourgault Australia delivers to local farmers for durability and efficiency. Find the right setup for your farm on this link.

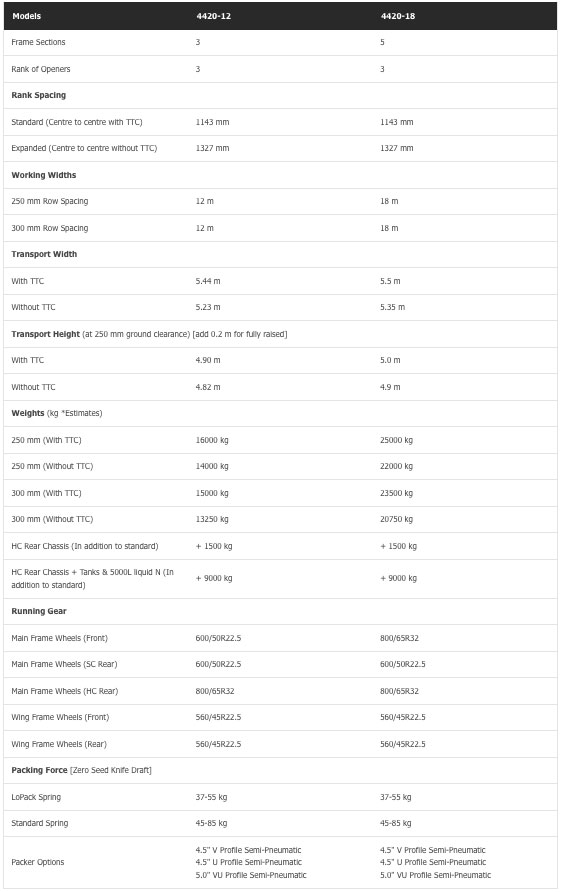

Bourgault 4420DKD Deep Knife Drill specs