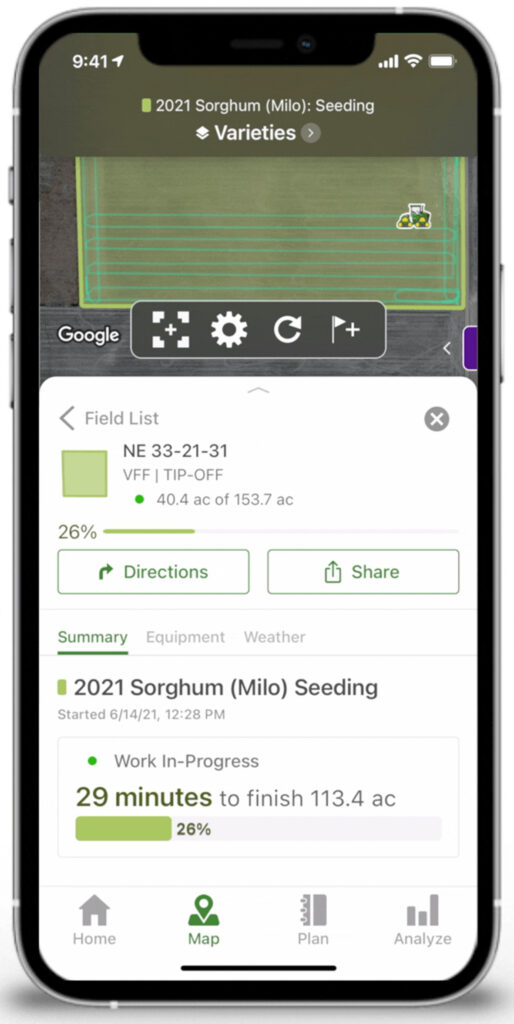

The latest round of John Deere Operation Center updates includes a countdown to the time remaining on the job

Machine monitoring steps up a notch as John Deere perfects tracking input application and record keeping with a level of precision and ease for the user with the latest Operations Center™ update.

John Deere Australia and New Zealand, Precision Agriculture Manager, Benji Blevin, said the most significant updates for Australian farmers included the expansion of John Deere’s input product database, and Operation Center’s ability to provide ‘estimated time remaining’ for tasks to be completed in the paddock.

“The latest update includes a number of improvements that will directly increase productivity for farmers’ businesses through time-saving and management insights,” Mr Blevin said.

“Prior to this update, growers in Australia had to manually input their own product information into Operations Center, which led to errors in record keeping and ultimately unusable data.

“Now operators can select products from more than 3500 varieties, 5000 chemicals, and almost 1000 fertiliser lines specific to Australia, ensuring they are capturing accurate records against farm operations including product name, brand, and registration number.

“This is an important update, as products form a key part of digital work plans that can be sent to machines wirelessly, ensuring that the right product is applied to the right fields and with the right rates.

“It will also improve the data available for farmers to make improved decisions for the next season,” Benji Blevin added.

Monitor machine performance

As part of this latest upgrade, farmers will also receive Uber-like updates on the efficiency of multiple machines in a paddock with the addition of the new function, Estimated Time Remaining.

“Operations Centre mobile will now provide farm managers with near real-time estimates on activity in a paddock,” Benji Blevin explained.

“Estimated Time Remaining applies data science to current and historical productivity to provide an accurate calculation of how long it will take a single machine or multiple machines to complete paddock work.

“The calculation, which updates every five minutes, is based on a number of factors such as turn times and machine configuration.

“Now farmers will know, to the minute, how long it will take to complete the work in the paddock before the rain sets in or the exact time a tender truck needs to meet the sprayer.”

Another effective farm management function included in the update is the ability for managers to track the amount of time a machine stays idle.

“A timer begins when any equipment begins idling and continues counting up until the machine is back in action again,” Benji Blevin outlined.

“All these machine monitoring features alert farmers on potential inefficiencies in their operations and provide invaluable insights for the better management of labour and flow of operational activity.”

Further updates to the John Deere Operations Center include:

Improved map experience

The new and improved map page in Operations Center web has simplified farmers’ experience of monitoring Paddock work and equipment from the office.

The update also allows farmers to select multiple partner organisations to view equipment information, as well as visualise complete location history including direction of travel and a time filter.

Machine Analyzer updates

For the first time, farmers will now be able to compare the performance of older machines that are no longer in your current fleet with replacement equipment.

This function will provide valuable insights into the performance of new machinery investments.

Equipment management tool

The new equipment management tool enables farmers to view and manage their entire fleet in one place, including machines, implements, and precision ag devices. For more information about the updates, go to the John Deere website or contact your local John Deere dealer.