Roesner has taken Multispread models to a higher level with their MDC app for secure machine calibration and operation while in the paddock

Developed and manufactured by Roesner Pty Ltd a family run company with a proud 122-year history, the Marshall Multispread holds the unique position as Australia’s top selling spreader.

Launched in the 1980s, the Marshall Multispread was developed in response to changing farming practices and local demand for a spreader that could handle a wide variety of ameliorants.

Since its initial launch, no other locally manufactured spreader has been able to combine the high standard of build with the continual innovation and product refinement that has set Multispreader models apart.

Marshall Multispreader models have provided local farmers with a cost effective and efficient method of spreading a variety of fertilisers in a wide range of applications, from small mixed farms to broadacre grain properties, vineyards and market gardens.

The Marshall Multispread remains Roesner’s best-selling product line to date, with more than 11,000 manufactured.

Ahead of the curve

Firmly committed to staying ahead of industry trends and changing customer demands, Roesner has ensured the Marshall Multispread has kept pace with an ever-changing agricultural industry.

In 2013, the company diversified into software and electronics to develop operating systems for the fast changing precision agriculture market through advanced technology, Roesner took the Multispread to a new level of accuracy.

The first software product, the Multispread Calibration app was released in 2013, followed by the award-winning Multispread MDC app in 2015 – one of the first hardware systems for ag machinery based on mobile device technology in the world.

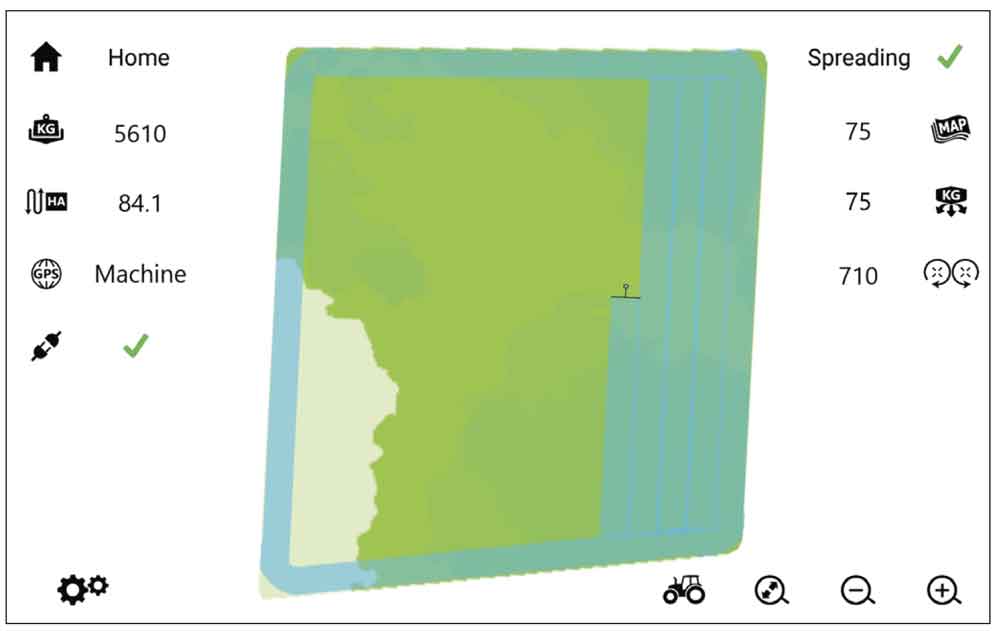

The smartphone app delivers up-to-date machine calibration and operating information to mobile devices in the paddock.

Then in 2018, Roesner acquired Precision Agronomics Australia, an industry leading company at the forefront of precision farming and variable rate technology.

The Roesner MDC system was merged with PAA’s Ratex system, and this rapidly accelerated the development of the i4M brand of machine controllers, mobile apps and web-based systems.

Developments boost efficiencies

Now, as the cost of inputs continues to rise, Roesner has released two additional systems, the D3 Spinner System and i4M Tracer GPS to further improve the Multispread operation and enable precision placement of fertiliser.

The result is these two systems give farmers the advantage to achieve greater efficiencies and maximise their productivity.

The D3 spinner system and i4M Tracer GPS ensure spreading efficiency is maximised through accurate placement of fertilisers at wider operating widths and reduced overlaps.

The D3 spinner system is the result of over three years of research, design and in-paddock testing with a range of different fertiliser types and in different ground conditions.

Designed and independently tested to achieve accurate spread patterns up to 36m with Urea and other granulated fertilisers, the D3 system incorporates a new spinner vane design, a central spinner cone and a deflector chute.

“The D3 spinner is the result of over 300 physical tests both in a controlled environment and in real paddock conditions,” Roesner Technical Director Matthew Roesner added.

“We’ve aimed at achieving the widest possible spread width with an even coefficient of variation to allow for changes in fertiliser properties and wind conditions – in essence, less margin for error in the paddock.”

The upgraded D3 spinners are supplied on all new Multispread machines and are also available as a retrofit kit to older model machines.

Meanwhile, the i4M Tracer GPS couples both coverage mapping and auto-shutoff functions with the popular i4M Variable Rate spreader controller.

The i4M system is developed by Precision Agronomics Australia and is a cost effective variable rate control system that is well proven in the paddock.

“The i4M Tracer GPS is a unique product, it uses an Android tablet and precision GPS receiver mounted on the spreader, to achieve coverage mapping and auto-shutoff independent of tractor GPS systems,” Matt Roesner concluded.

To find out more about the Roesner manufactured in Australia range of Marshall Multispread models see more at: roesner.com.au and contact your local dealer here.

While the Marshall Multispread spreader app can be downloaded here.