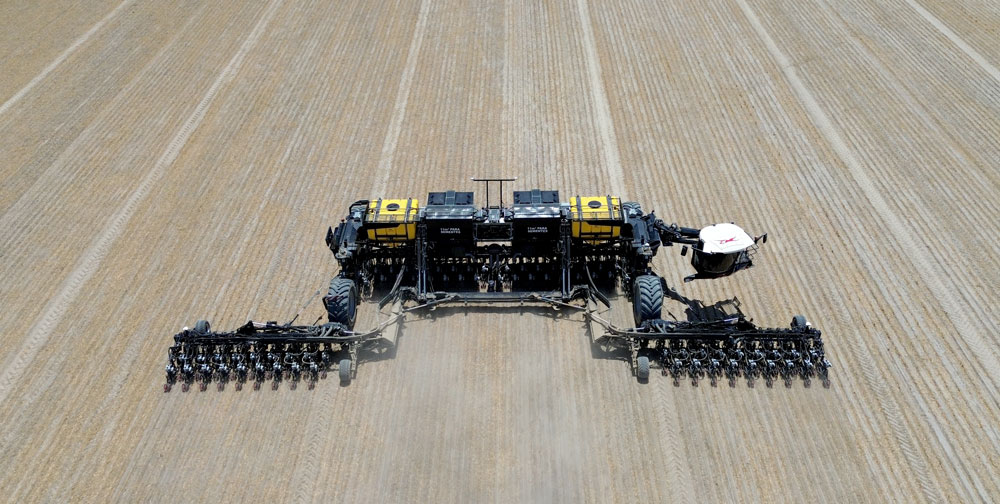

The power platform developed to replace a tractor harvester and sprayer reveals an autonomous model while continuing to upgrade its full cab variant

Experienced industry observers view the NEXAT power platform as the greatest threat ever to traditional tractors, one that will advance farming into an era equivalent to the time engines took over from horses and manpower.

Already available to place a factory order and in operation on large-scale farm properties in North and South America, this is the power platform destined to change what farmers park in their shed, as one platform will complete all tractor, harvesting and spraying tasks.

See the exclusive NEXAT power platform launch story on this link.

NEXAT sends a clear message to those willing to accept change for a more profitable agriculture of the future.

Even though a NEXAT hasn’t reached us down-under, this new era in agriculture is already well underway as over the past two years, NEXAT has proven in practice that this system enables a significant reduction in operating costs by up to 25% compared to conventional methods, marking a milestone in terms of profitability and resource efficiency.

This efficient and innovative crop production system has been developed by father-and-son team, Klemens and Felix Kalverkamp and marking a difference to power platforms that preceded, they are still firmly in control.

“Our goal is clear, NEXAT will be the most economical arable farming system on the market, gained through efficiency, paddock performance, and intelligent technology,” explained managing director Felix Kalverkamp.

Underlining the company’s commitment to offering holistic solutions for efficient and sustainable agricultural processes, Felix adds, “We are demonstrating that profitability, sustainability, and intelligent technologies are not contradictions, but together pave the way.”

Large-scale technology updates

Consistent with the continuing development of an autonomous model, improvements to the full cab with operator model available for factory order in North and South America continue unabated.

The expanded product portfolio now includes seeding up to a 28 metre working width bedded down with direct seeding technology from K-Hart and precision seeding technology from Baldan (Brazil).

With increased seed hopper capacities, paddock outputs of up to 200 hectares from each filling are now possible for soybeans, and even more for corn. Performance figures that highlight the NEXAT’s power and efficiency for large-scale operations.

“With our system concept, we combine efficiency, precision, and profitability, whether on

100 or 10,000 hectares,” Felix Kalverkamp points out.

Implement range expansion

NEXAT has continued to expand its range of implements, continuing its policy of working with independent manufacturers in each country where the platform is offered.

Additions to the implement line-up include many latest release models from leading makers including

• the next generation of the Väderstad Tempo NX27

• Väderstad Cultus HD cultivator

• fertilizer spreader from AMAZONE – ZG-TS 200001

• fine cultivator from BAARCK

• prism roller from Güttler – Matador 1360

• direct seeder from Canadian manufacturer K-Hart

• knife roller from Eidam Landtechnik GmbH – innoMADE MW-X

• and a row hoe from Einböck – Chopstar Max.

With these additions, NEXAT now covers a wider range of jobbing options, including soil cultivation, seeding, fertilisation, and crop protection and for harvesting with the NECXO harvest module.

All operations are fully integrated into the modular NEXAT carrier system, and in return, growers will be rewarded with maximum workflows from implements that are optimised, with operating costs reduced by the system’s economic value.

Adding autonomy automation

Another key theme of NEXAT’s evolution is the consistent development toward highly automated processes leading to future autonomous operation, in addition to the full cab variant.

The combination of electric wheel hub drives, a 360° rotatable cab, intelligent environmental monitoring, and centralised process control already enables largely automated and precisely coordinated workflows.

As part of ongoing paddock trials for autonomous operation, Engineers are introducing a crucial step with AI-driven and digitally connected implements that will provide practical applications under paddock conditions.

NEXAT will continue to focus on operator comfort, safety, and merge cutting-edge technology to create a benchmark for automated power platforms from machine control to optimisation at the farm level.

“Highly automated systems are another key to reducing labour costs while increasing precision and sustainability,” emphasises Felix Kalverkamp. “NEXAT provides the platform that makes this transformation both realistic and economically feasible like no other farming system,” Felix concludes.

Take a look at the NEXAT operating the 28m wide direct drill in this video link.

NEXAT key performance factors

Power and drive system

- Engines: Two 405 kW (550 hp) diesel engines, providing

a combined output of 809 kW (1100 hp). - Drive: The engines power generators, which then supply

electricity to four individual 160 kW (218 hp) electric

motors, one for each wheel. - Alternative power: The system is designed to eventually

be powered by green hydrogen fuel cells.

Dimensions and performance

- Maximum speed: 25 kph.

- Working width: 6 to 24 metres, depending on the attached module.

- Spray boom width: Up to 70 metres.

Key features

- Modular design: The power platform has interchangeable implements

for different farm tasks, can be swapped by one person under 10 minutes. - Controlled Traffic Farming: The wide-span system allows for CTF where

only about 5% of the paddock is driven on by the machine. - Integrated system: NEXAT combines multiple agricultural machine functions,

such as tillage, seeding, plant protection, and harvesting, into one platform.